Discover how an integrated digital and visual approach to colour management of plastics can help reduce costs, speed up manufacturing processes and minimise your environmental impact.

VeriVide’s solutions help masterbatch manufacturers and plastics processors to control colour quality efficiently for elastic, opaque, translucent, transparent, smooth or rough textures.

With our DigiEye colour management and inspection system for plastics, manufacturers can digitally measure the colour data of plastic samples at any stage in the manufacturing process. This is particularly beneficial both before and after the moulding or extrusion process, as the temperature from the compression can affect the colour and appearance of the plastics.

The high-resolution images created in DigiEye can be instantly shared with brands and designers for approval, streamlining your colour inspection workflow.

VeriVide’s Light Booths supply optimised lighting conditions to evaluate the appearance of samples, detect colour variations and inconsistencies, and make colour comparisons before and after moulding procedures.

UltraView is the ultimate in LED precision for accurate colour sample comparison.

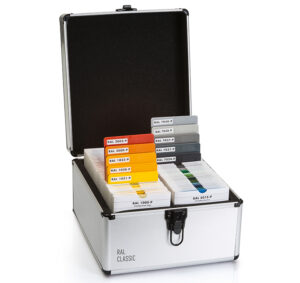

With Pantone plastic colours and RAL plastic standards you can specify the exact colour you need across your supply chain, minimising complications and reducing delays in production.

Plus, by achieving accurate colour matching from the get-go, you can avoid costly mistakes and re-runs, while also reducing waste – and your carbon footprint.

If you are at the start of your colour matching journey, we advise starting by choosing the correct colour standards. As master distributors of Pantone, RAL and NCS, we have the expertise and knowledge to guide your decision making. Contact us via email on colourstandards@verivide.com or call us on +44 (0)116 284 7790

If you have the correct colour standards but wish to know more about how our lighting cabinets and DigiEye software can benefit your colour matching process and how these elements can fit into your industry and product designs, please email us at enquiries@verivide.com or call +44 (0)116 284 7790.