When it comes to food and drink, colour is an indicator of flavour, freshness and safety. That’s why food and liquid colour measurement is an essential part of food quality testing.

VeriVide helps you assess colour throughout the development, processing and shelf life of your products – ensuring your customers have the confidence (and appetite!) to buy them.

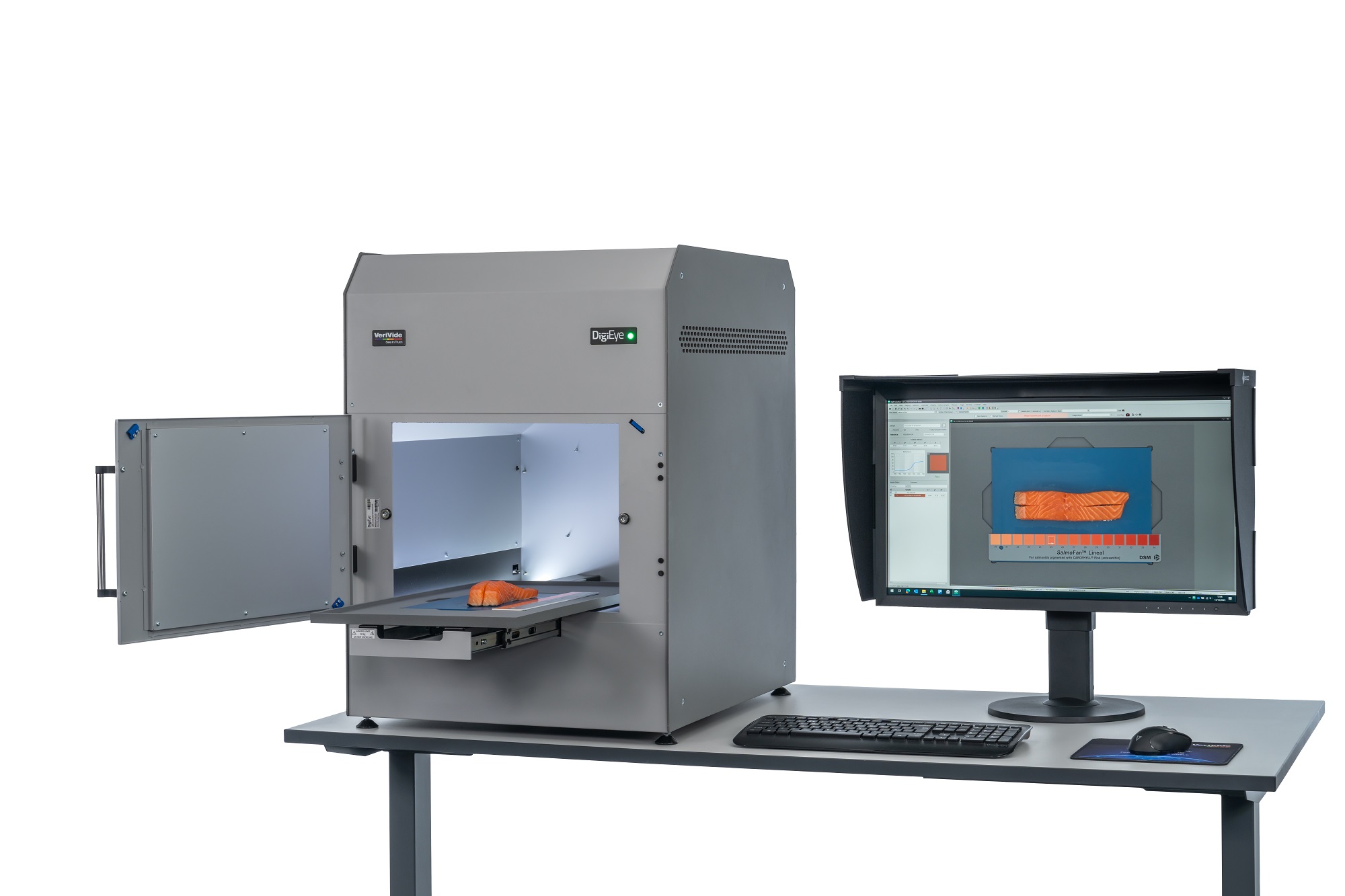

DigiEye is your solution for food colour measurement for all types of produce, including liquid, powdered, granular and fresh. Our non-contact, non-destructive system is able to perform detailed colour analysis, even down to the smallest pixel. Once images are captured, you can digitally communicate them across your supply chain so that products can be checked against the approved colour standard. You can also archive images for batch traceability and reporting.

With DigiEye you can ensure:

DigiEye enables you to carry out food and liquid colour measurement using industry colour systems (CIELab or HunterLab) and in-built food-industry scales. For more information download the DigiEye for Foods datasheet or contact enquiries@verivide.com

Production-line operators can assess products in a controlled viewing environment using UltraView – our tuneable, all-LED light booth.

Our VisionView cabinets have an integrated DigiEye viewing monitor, enabling quick and easy comparison between your physical products and the on-screen standards.

See how VeriVide can speed up your food quality testing – be it for bread, butter and everything in between:

We’ve supported the food and drinks industry for 50 plus years, helping brands, manufacturers and scientists to maintain product quality control – all while cutting down on costs and wastage.

With VeriVide you can be sure that every biscuit in every pack looks the same; your orange juice is just the right orange; and your plant-based meat looks like the real deal.

For more information about how DigiEye can transform analysis of your food and drink products visit Case Studies or complete the contact form and a member of the DigiEye team will respond.

If you are at the start of your colour matching journey, we advise starting by choosing the correct colour standards. As master distributors of Pantone, RAL and NCS, we have the expertise and knowledge to guide your decision making. Contact us via email on colourstandards@verivide.com or call us on +44 (0)116 284 7790

If you have the correct colour standards but wish to know more about how our lighting cabinets and DigiEye software can benefit your colour matching process and how these elements can fit into your industry and product designs, please email us at enquiries@verivide.com or call +44 (0)116 284 7790.