Matrix and complex materials can make textile quality control a challenge. With VeriVide’s innovative solutions, you can ensure accurate, consistent colour management across all types of technical textiles.

Technical textiles are designed for function rather than aesthetics. They span a broad range of industries and applications – from seatbelts and parachutes to sportswear, medical dressings, and more.

The accurate assessment of colour and appearance not only ensures visual consistency across a product range – it’s essential for safety, durability and functionality.

Textile quality control procedures can be difficult in technical textiles, as they are produced from complex or matrix materials. These may include woven and non-woven fabrics, microfilament, polyester or nylon yarns and acrylic, polymer or carbon fibres.

The variability in fibre composition, weave structure, and surface texture makes consistent colour measurement more difficult. VeriVide’s solutions are designed to meet these challenges, enabling precise and efficient assessments for every kind of material.

VeriVide’s systems are built to simplify the complexity of colour control in technical textiles.

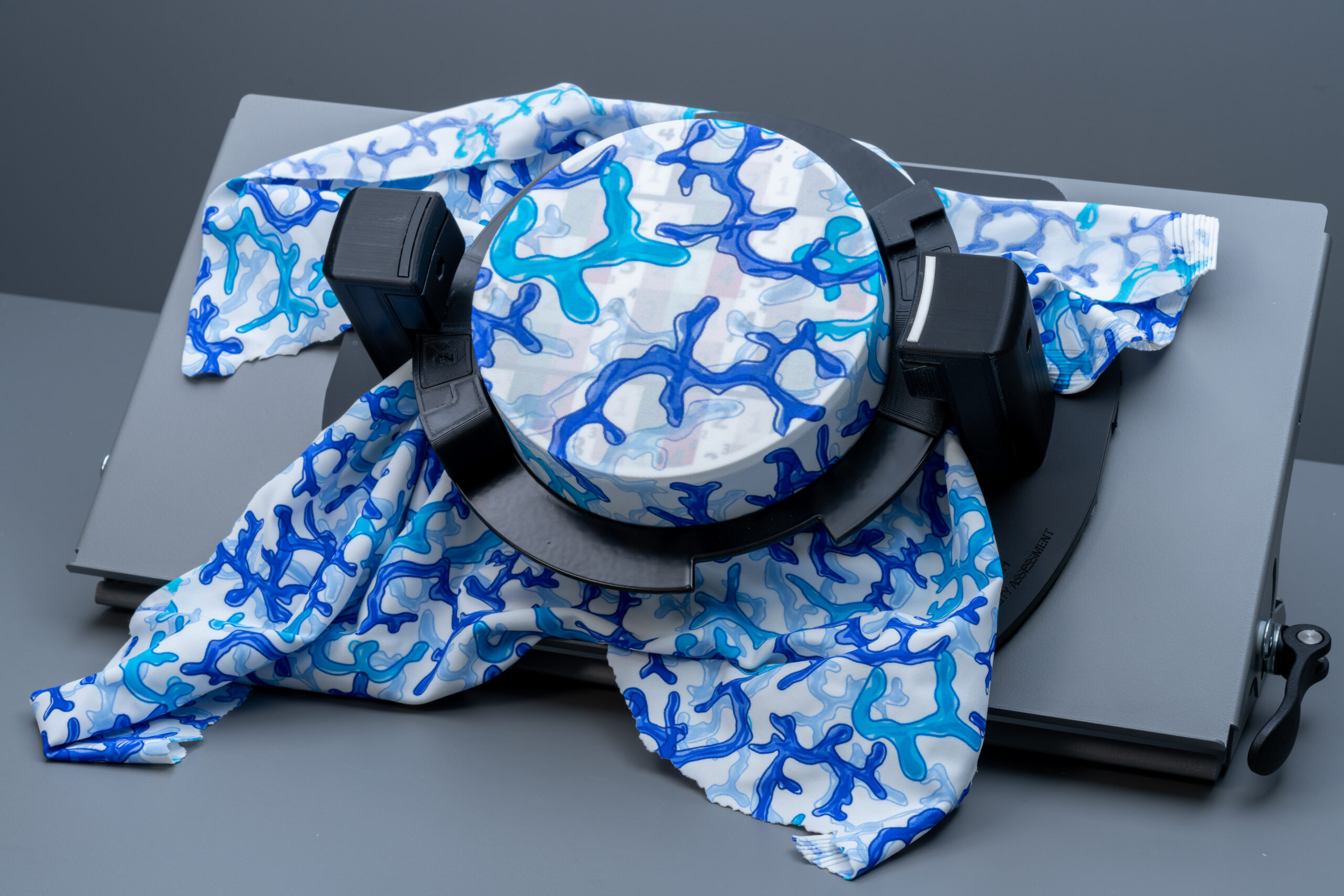

Our All-LED DigiEye System captures high-resolution images of even the most textured or variable surfaces, allowing for non-contact, objective colour measurement. These images can be instantly sent across your supply chain for fast assessment and approval.

Measuring and evaluating colour and appearance digitally enables manufacturers to speed up colour development, share and communicate objective colour data across the globe and achieve colour consistency throughout their supply chain.

DigiEye can be easily configured to assess tapes, belts, ropes, nets, membranes, multi-layered composites, ‘smart’ textiles, recycled materials, coated textiles and technical safety fabrics.

Our All-LED light booths are essential for assessing colour and appearance throughout the production process. With UltraView you can assess items of different sizes and textures under standardised lighting, while VisionView also allows you to compare your items to a digital on-screen counterpart.

Both UltraView and VisionView are supplied with CIE standard illuminants and a variety of LED point of sale lighting options.

VeriVide’s technology is trusted across industries where technical textiles play a vital role. These include:

You can be sure that your textiles meet global industry standards with our textile testing equipment. Whether you want to test for colour fastness or pilling; opacity or abrasion, VeriVide’s easy-to-use tools have all your needs covered. OmniStretch is the new apparatus for analysing elastane grin and opacity of stretch fabrics.

As official suppliers of Pantone, NCS, and RAL colour standards, we can help you achieve seamless colour matching and regulatory compliance – from concept to finished product.

If you are at the start of your colour matching journey, we advise starting by choosing the correct colour standards. As master distributors of Pantone, RAL and NCS, we have the expertise and knowledge to guide your decision making. Contact us via email on colourstandards@verivide.com or call us on +44 (0)116 284 7790

If you have the correct colour standards but wish to know more about how our light booths and DigiEye software can benefit your colour matching process and how these elements can fit into your industry and product designs, please email us at enquiries@verivide.com or call +44 (0)116 284 7790.