Colour measurement of food and drinks is essential

It is well known that colour influences our purchasing decision, some colours we prefer to others and others are associated with branded items.

Colour is one of the main attributes that helps us evaluate the quality of food and drink, we judge freshness of the product by its appearance.

But how does colour influence our food and drinks buying decision?

Colour is the most important element in food and drinks that intrigues our flavour sensor. Colour creates expectations to people regarding the taste of food and drink, experiments have shown that if we colour orange juice red then we expect it to taste of strawberries!

We eat with our eyes.

By checking the colour in food and drinks, we try to make the right choice for our tastes, estimating if the product is going to be sweet, salty, sour, or bitter.

For example, we try to determine from the colour if the red apple is sweet enough for our taste. We buy mature bananas if we will consume them in the next 2 days, but we prefer unripe fruits if we want to keep them fresh in our cabinets for a whole week.

What if the colour of your product fails to meet the visual expectations of the consumer?

Many times, we are fooled by our sense of sight, as the food or drink does not taste as we thought. In other cases, we are unable to assess the colour of the food products such as yoghurt or beans until we are at home, armed with the tin opener or when opening the package.

This is the time when the integrity of your brand is challenged with financially damaging consequences if you have got the colour wrong. Achieving the desired colour in your food and drinks is crucial for business success.

“I’m not eating that, it looks wrong!

They’ve obviously changed something – please don’t buy that brand again”.

Maybe the sauce in a can of baked beans ‘looks pale compared to normal’ or the perception of a lack of visible ‘chunky bits’ in a strawberry yoghurt will entice your customer to seek something ‘more fruity’ elsewhere. No brand or food company want to be in that position.

Controlling Colour with the DigiEye System

Measuring the colour of food and drinks helps you to control the colour and product’s quality, meeting consumers’ expectations. By avoiding disappointed customers you will also avoid returns and waste.

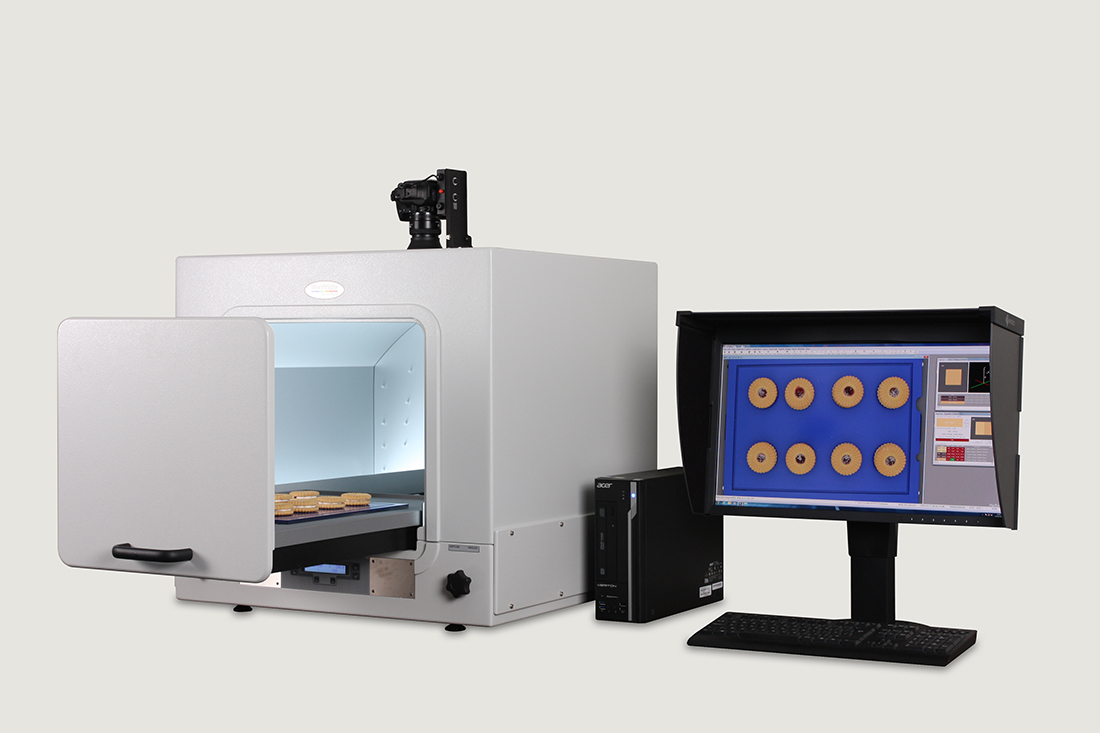

DigiEye is a non-contact, digital colour measurement and imaging system with many proven applications for an extensive range of foods and ingredients. With DigiEye, accurate and repeatable colour measurement of food is possible. Whatever the format of the food substance, solid or liquid, powder or granule, both the colour and appearance can be assessed. When taking colour measurement of food, there are no special preparation steps necessary. The food sample is not destroyed, and the sample can be put back onto the production line without any loss.

DigiEye can assess the different visual components as a percentage of the total appearance which is undoubtedly one of the first of our various sensory inputs to influence consumer selection.

Example

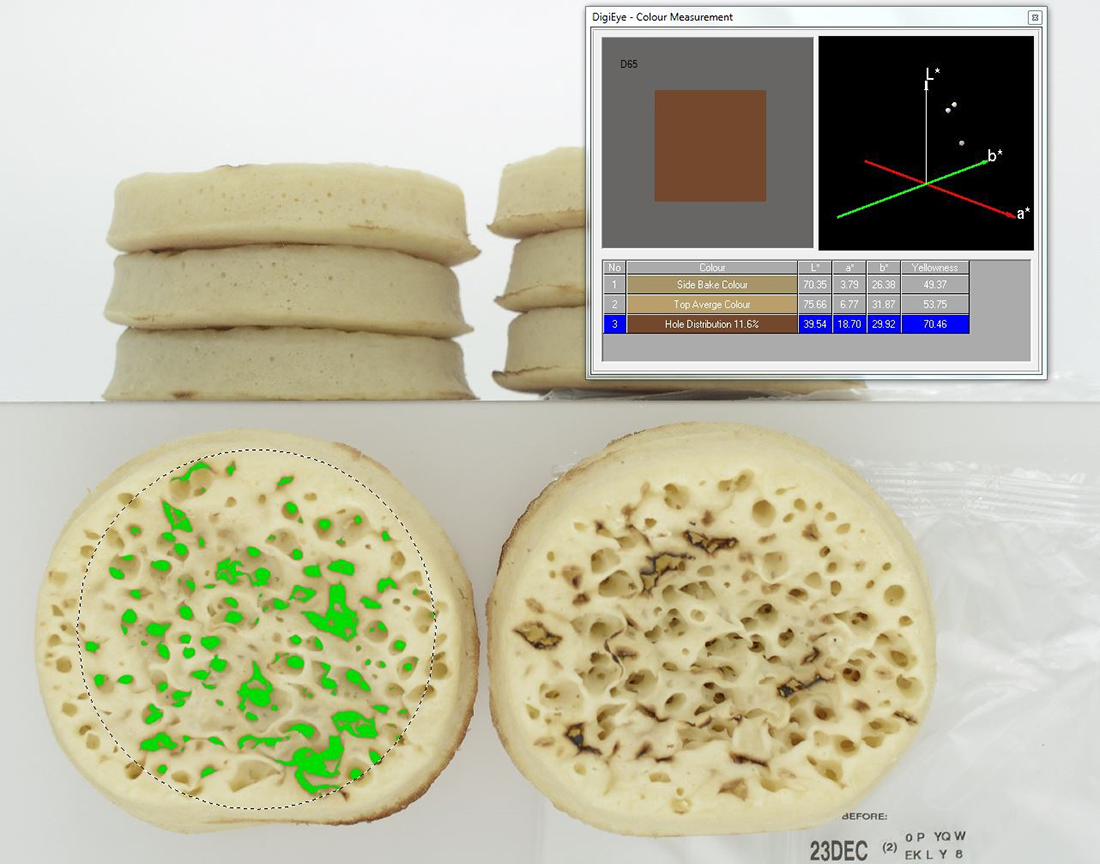

In the following example, we measure the colour and appearance of Warburtons crumpets. By using a 45-degree mirror table, a single image can capture the side and top bake of the crumpets at the same time. Other imaging analysis tools can be used, like checking the uniformity of the holes across the top of the crumpets. The Uniformity Sorting function can be used to assess the uniformity of colour across the crumpet.

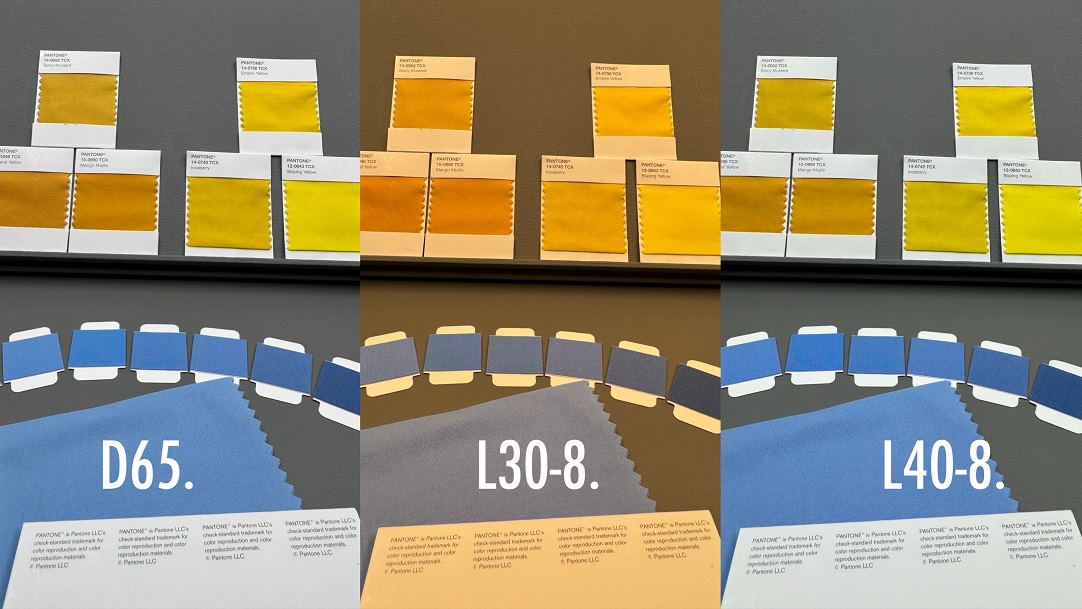

DigiEye software relays data to a calibrated monitor and optional printer for instant comparison and, if needed, colour-accurate printing of images for use as master product standards.

Image: We measure the colour of Warburtons crumpets with VeriVide’s DigiEye System

Consequently, the quality control team can detect immediately if a batch is out of tolerance against the agreed visual standard. They prevent out of tolerance products being released to the supermarkets.

With the right measurement tool, you can ensure the product purchased in-store is of the highest quality for your customers.

Applications

The following list is DigiEye applications for colour measurement of food and drinks:

- Quality Control

- Photographic Standards

- Tolerance Management

- Visual Inspection

- Product Research & Development

- Laboratory Analysis

- Instrumental Measurement

- Multi-Sample Evaluation

- Colour Stability Analysis

- Post-Harvest Storage & Shelf Life Assessment Trials.

Image: VeriVide’s DigiEye System for colour and appearance measurement

Find out more by viewing our solutions for the food and drink industry or download the DigiEye for Foods datasheet

Feel free to contact us by email to enquiries@verivide.com or phone to +44 (0) 116 284 7790. We are happy to help you with any colour challenges or answer your questions.