Better control colour fastness in clothing and keep customers happy!

The term colour fastness (also known as ‘colourfast’) is used in the textile industry to describe the resistance that a dyed fabric has to its colour running, fading, or rubbing off onto other materials. There are different types of colour fastness tests, including resistance to light, ironing, bleaching and perspiration. The most common testing methods are colour fastness to washing and rubbing/crocking.

Apparel and textile manufacturers need to ensure that when a customer washes an item of their clothing at the recommended temperatures; there is minimal colour fading (e.g. a black top comes out grey). Customers must be confident the colour should not run into other items of clothing (e.g. a red sock staining a white sheet pink) and when it is worn the colour should not rub off on other clothing or materials (e.g. denim leaving a blue tinge to a white leather sofa).

Why Colour Fastness testing is important

Although many brands and retailers have started to invest in more environmental-friendly materials such as natural dyes from plants, animals and minerals*, chemical dyes are still commonly used in apparels.

Colour fastness to washing or rubbing can prevent the pollution of water eco-system, reduce wastage as well as protect the human skin from the chemical dyes. Therefore, colour fastness grading is a crucial stage in the quality control of fabrics.

Rich and dark colours (e.g. black, red, navy etc.) are the most problematic for colour fastness issues compared with lighter colours (e.g. whites, pastel colours etc.).

Prior to manufacturing the final product, it is wise for brands and retailers to assess the colour fastness of the prototype materials. By checking the colour fastness grading of their suppliers’ materials, brands can ensure customer satisfaction.

Before a garment is sold, the final product needs to tested again in order to highlight any issues. Doing this before a garment is put on sale can save the company a lot of turmoil from disgruntled customers. How can you test the colour fastness? Let’s see two different alternatives.

Traditional test of Colour Fastness

To get representative results about the colour resistance of apparel to rubbing or washing, the testing should conform to ISO 105 or AATCC standards for colour fastness.

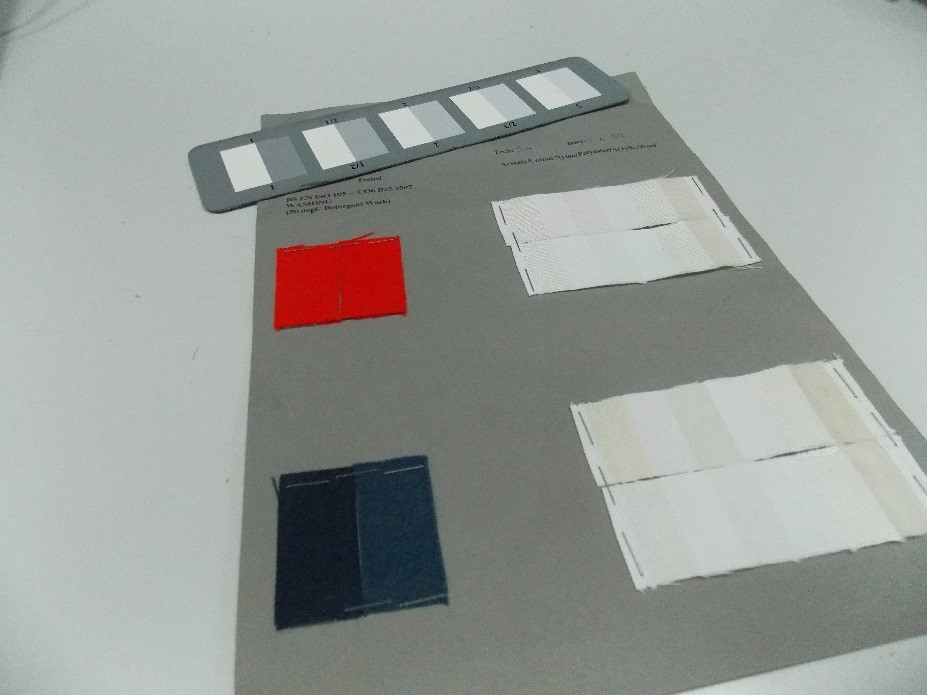

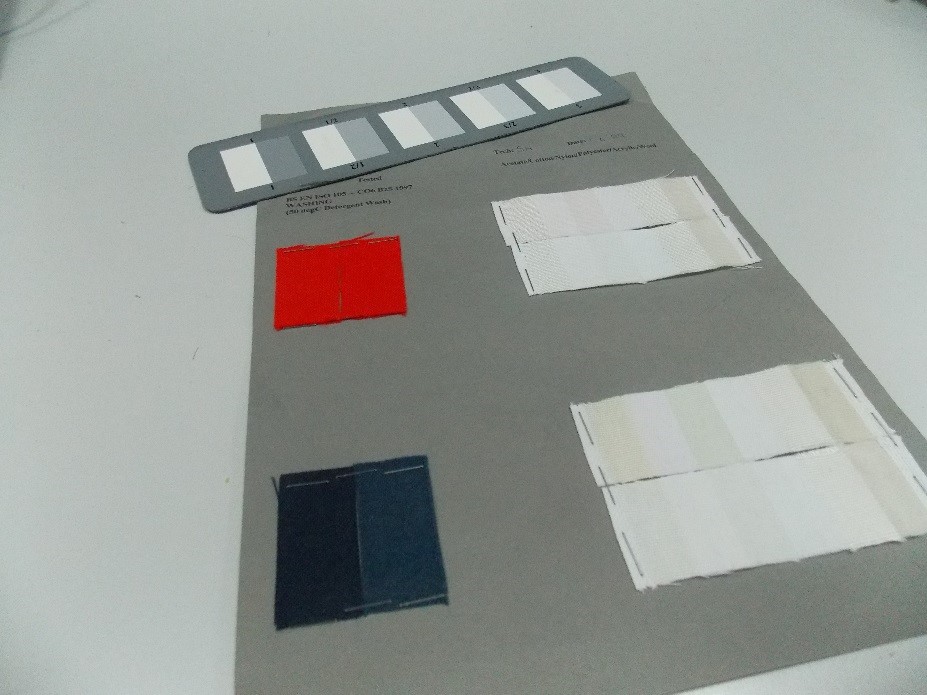

The Quality team assess if the fabric is fading after detergent washing with a commercial laundering product within a Light Booth by using a set of grey scales for shade change. For colour pick up by other fibres, a multifibre strip is washed with the sample and is graded using the grey scale for staining. A Fabric Technologist grades the colour fading from 1 (the highest change) to 5 (no change in colour) to determine if the fabrics are colourfast or not. Make sure you do not touch the grey scale with your hands, as it can influence the results.

Image: Grey scale for testing colour fastness (source: VeriVide)

Most clothing requires a fastness grade of at least 4 or above on the staining scale.

A Light Cabinet is the ideal environment for this testing, as fabrics and apparels can be viewed under standardised illuminants (e.g. D65 artificial daylight). The test methods also require a 45 degree angled of viewing, provided by a Tilting Table.

Image: VeriVide’s Colour Fastness Cabinet (CF 60)

Digital test of Colour Fastness

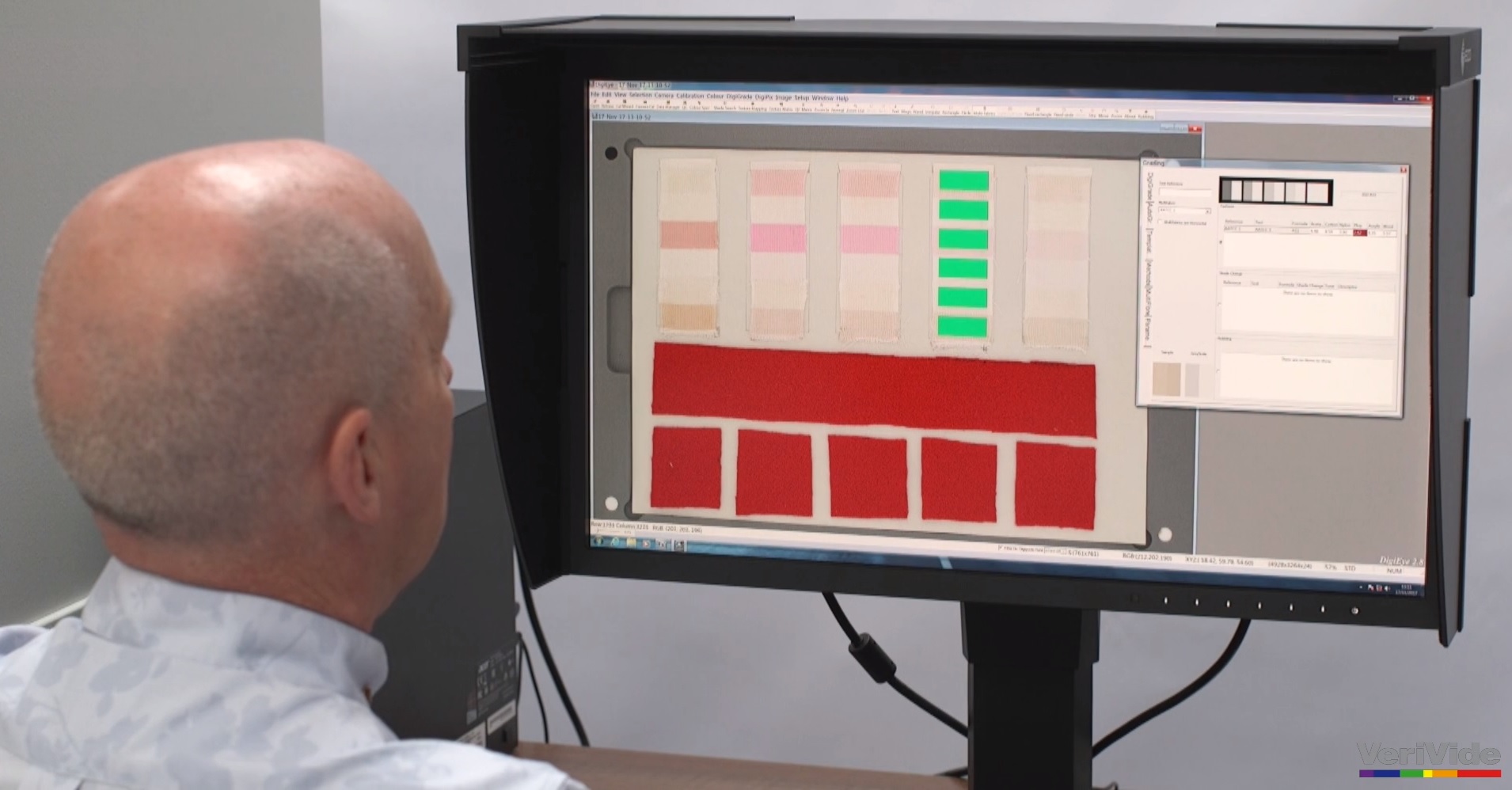

An alternate approach is to test colour fastness digitally through our DigiEye DigiGrade software. The digital grading is a more accurate and faster method, meeting the ISO 105 – A:11 standard.

The test samples are imaged in DigiEye cube and then they are evaluated digitally through DigiGrade software. Manual grading, where the user selects the assessment area, is performed or auto-grading of results is pre-programmed. Fabric technologists and Quality teams evaluate samples objectively and repeatably for washing fastness results, dry and wet rubbing, and light fastness.

The digital grading with VeriVide’s system offers a speedy test process and eliminates subjectivity. Thus enabling manufacturers and brands to make the right decisions for fabrics.

Image: VeriVide’s DigiGrade colour fastness testing system

The future of natural dye

Many brands and textile manufacturers want to move away from using artificial synthetic dyes and start using natural dyes. It has been rumoured that ‘Raw Denim’ is making a comeback which uses the natural indigo dye. Whilst this may be more natural and ethical, natural dyes cannot be specially treated for colour fastness, therefore care is needed.

If you would like to find out more information about the digital grading of colour fastness test, please do not hesitate to get in touch on 0116 284 7790 or send an email at enquiries@verivide.com.

*Yusuf, M., Shahid, M., Khan, S. A., Khan, M. A., & Mohammad, F. (2015). Dyeing studies with henna and madder: A research on effect of tin (II) chloride mordant. Journal of Saudi Chemical Society, 19, 64–72.