Without any doubt, consumers are more and more demanding about quality and they easily reject products that don’t fill their expectations. Consequently brands require more effective solutions to achieve colour and appearance consistency with cost-effective and time-saving methods. The reproduction of product’s colour and appearance to specified standards is always a major challenge for many manufacturers.

From textiles to packaging, plastics or coatings if manufacturers cannot succeed with the colour and appearance consistency of their products, the sales are going to plummet. Therefore, colour and appearance measurement should be an indispensable part in the quality control procedure of your products. It is important to choose the right colour measurement device to ensure colour and appearance consistency.

What is colour and appearance measurement?

Consumers perceive the products quality from its appearance. Except for colour, there are many attributes that affect the appearance of the product such as texture, haze, defects and flaws which all contribute to the product’s appearance.

For example, the appearance quality of food relies on “the distribution of surface reflectance, the nature of internally scattered light and the pigmentation of the product”. On the other hand a textile’s appearance is assessed by factors as colour, pilling, wrinkling, staining, creasing, texture and draping.

Appearance measurement is referred in 4 main categories, “colour, gloss, translucency and texture”. At this point we have to highlight that appearance measurement is different from colour measurement. Detection of flaws, defects, contamination and stability of your product you are interested in appearance measurement.

Creation or use of an existing colour standard and colour measurement of your product against it ensures accurate and consistent colour reproduction. This is suitable on plain flat items and if you are only interested in the colour data, however, many products have appearance characteristics which affect the colour . Many of our clients prefer to measure the appearance as well as the colour of their product to gain the full picture of its quality. In the following example our client wanted to check the uniformity of colour across the biscuit.

Where is colour and appearance measured?

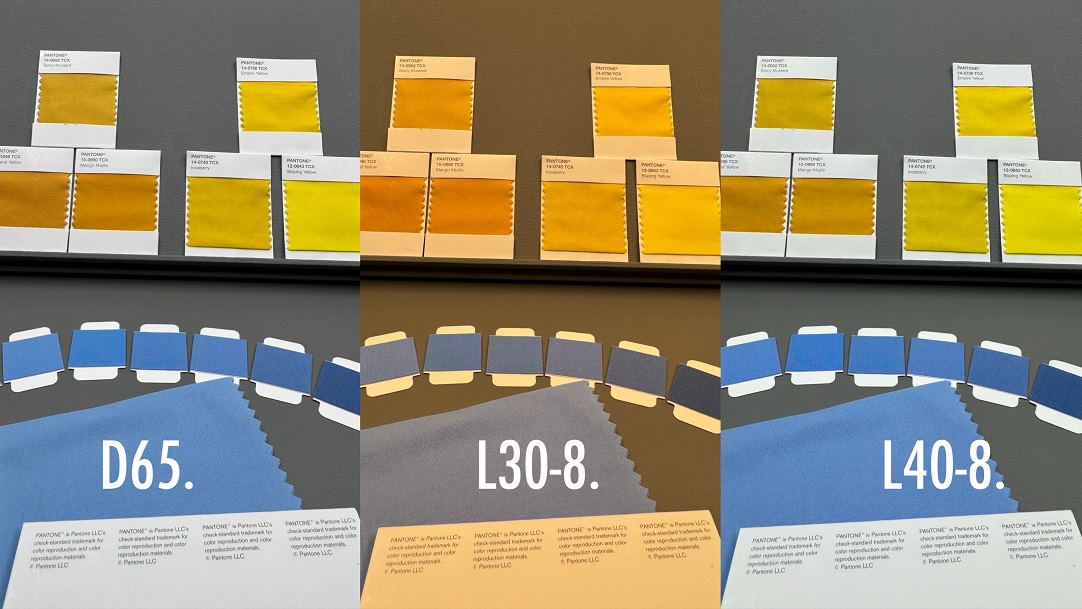

Depending on the production line, colour and appearance measurement can occur in different stages from the design and prototyping stage to the final production for evaluation of the quality. In the textile industry colour measurement is needed in two stages, one of the dyed sample (lab dip) to be used as the internal dyed standard and one for the bulk production which is fully finished.

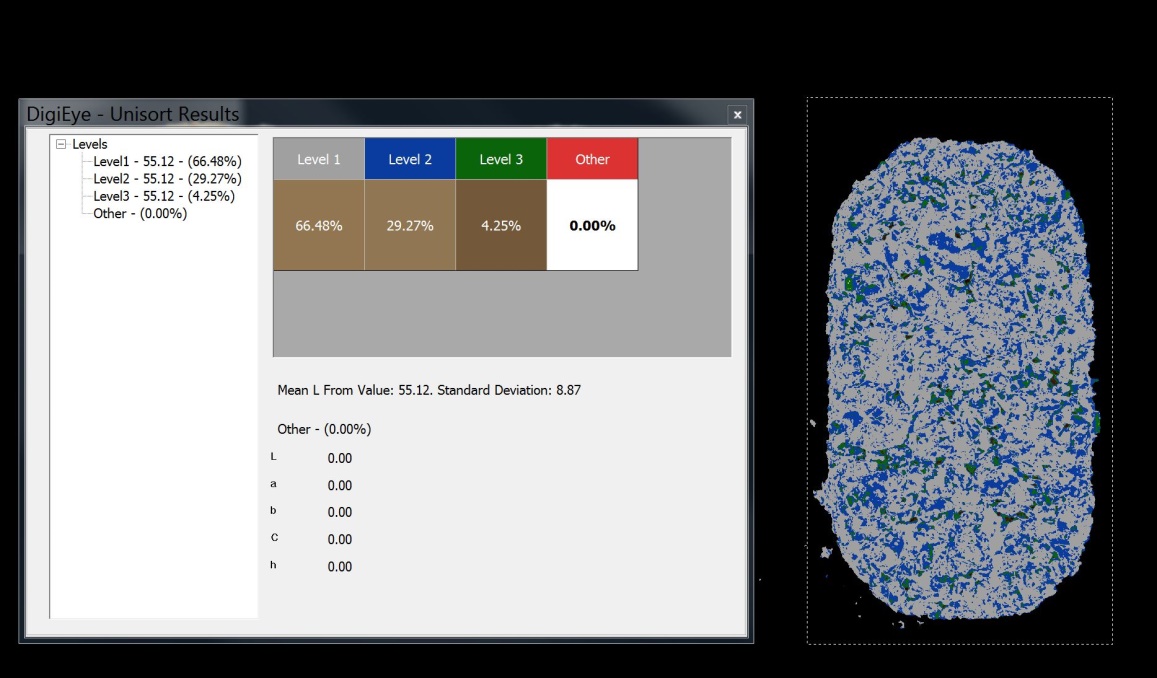

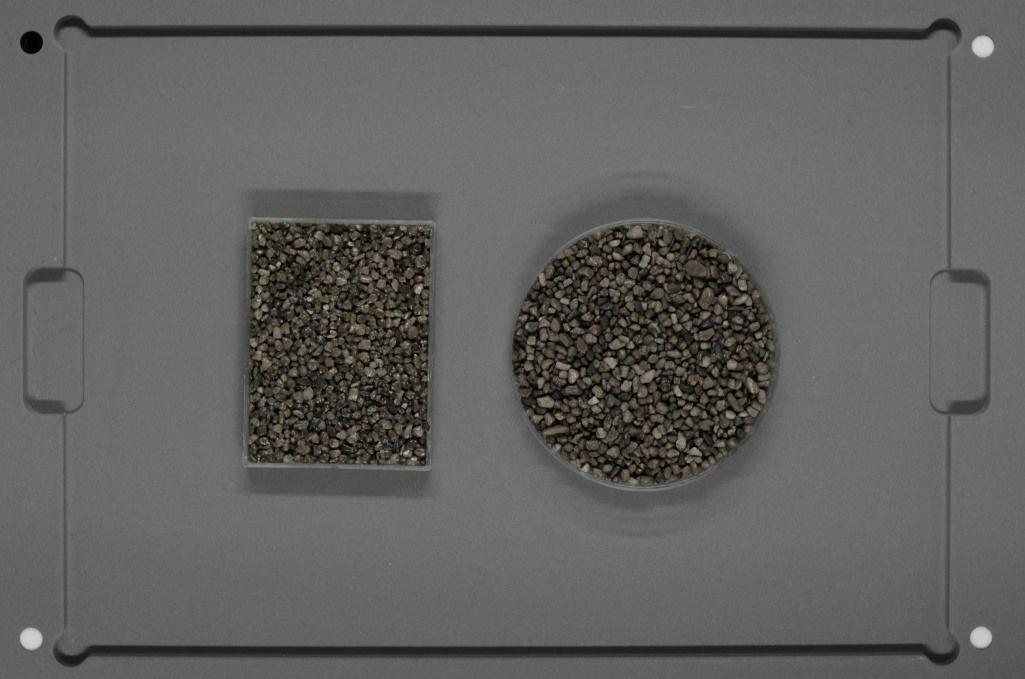

In the plastic industry, manufacturers usually measure first the colour of the plaque before the moulding procedure against an interim standard to ensure they will have the desired results in the final product. Temperature from the compression process can affect the colour and appearance. Consequently, the final product, in our case the master batch pellets (see the picture below), should be measured again after the moulding procedure.

Why colour and appearance measurement is important?

Many times we take colour for granted and we don’t realize the importance of it. Colour is the most important attribute of a product at the point of sale, defining also the quality appearance.

- Consumers make the final buying decisions depending on the visual elements of the product. The visual attributes of the product help us recognize the quality so, if the garment that we want has variation in colour, we question if the colour has been properly applied and fixed (unless it is tie dye of course!). We check if an automotive coating has any scratches and defects. Even in food and beverages, colour plays an important role in the attractiveness of the products, as we perceive the taste and flavour from its colour. For instance, depending on the colour of a banana skin, we can recognize the level of ripeness.

Also, ensuring colour consistency in your products is very crucial, as “colour connects a product to consumers more quickly than any other identifying features”.

Consumers are repelled by poor quality and they will reject product whose appearance does not appear to be “right”.

- Business and retailers use colour to create brand awareness. The consumer associates a colour with a brand and sometimes a product within a brand. Sometimes the products are selected from the stores’ shelves only from the colour. If a colour in the packaging doesn’t appear the same, like the following example, it could have a negative effect on the brand.

- You can save precious time and money, eliminating production loss.

Accurate reproduction of the same colour remains a huge challenge for many manufacturers. Especially, where surfaces such as gloss, metallic coatings or complex items like products from carbon fibre make visual assessment more difficult. In this situation it is even more important, to measure colour to speed up the quality process and reduce the wastage.

The need for colour consistency is more significant than ever needing adequate colour measurement devices to achieve it!

How to achieve colour and appearance consistency

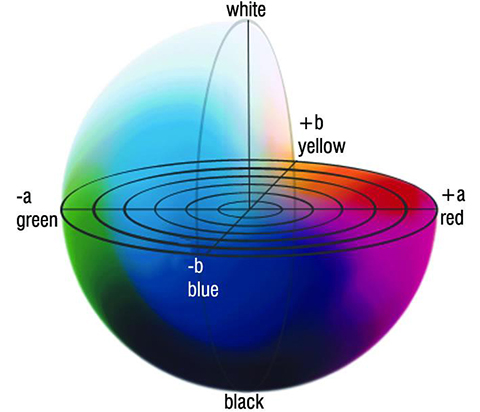

“Colour is an interpretation by the human brain obtained from the eye´s perception of visible electromagnetic waves”. An interesting fact is that our brain cannot remember colour neither describe it. We cannot reproduce colour with the same accuracy without measuring and applying the physical values of the colour.

Colour can be expressed numerically and this is the fastest and most accurate method for the reproducibility and repeatability of the colour. Innovative colour and appearance measurement devices transform the way of managing product colour and quality. Additionally the provide numerical data, helping manufacturers to communicate colour better and eliminate product’s wastage and rejection.

How to choose the right colour measurement device to ensure colour and appearance consistency

Choosing the right measurement instrument is important as you have to be reassured that the device understands the colour variables. Determining the product and application that you need the device to measure will help you to choose the right one.

First decide is your product flat or 3d? Is it opaque or translucent? Do you want to detect flaws on the product’s surface? Is it solid or liquid?.

Does the method need to be non-contact to avoid product damage in a food or beverage?

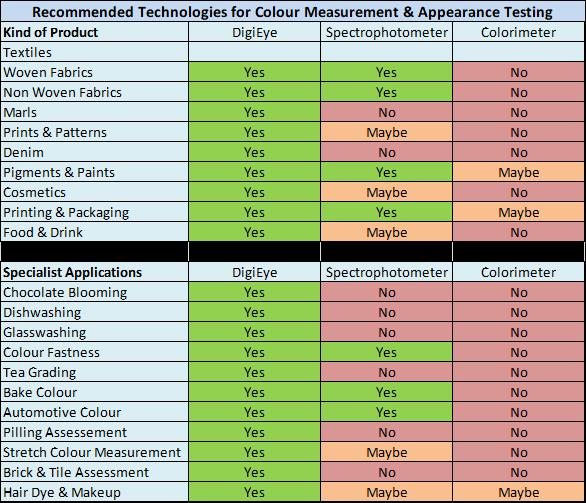

The below table will help you to choose the right colour and appearance measurement equipment, for your products and application.

DigiEye is a non-contact colour and appearance measurement system that helps you determine product’s quality, consistency and safety. A calibrated digital SLR camera captures outstandingly detailed images of your product. Colour data is recorded at millions of points with unvarying objectivity against the standards that you will set. VeriVide’s DigiEye can actually measure and assess product’s colour with its appearance for all industries.

Learn what kind of products DigiEye can measure? Check the video to find out its application.

Contact the DigiEye team on enquiries@verivide.com for a demo today