Many organisations and businesses have upgraded stores to LED lighting, giving a fresh, and overall clean look to displays and products. LEDs not only improves the store environment but reduces energy usage and helps to improve an organisations environmental footprint. It is a no brainer! Reduced energy consumption, reduced cost and reduced shareholder pressure surrounding environmental impact.

Whilst LED lighting provides multiple benefits to stores, it is essential to use an equivalent light in your light booth. When products are being designed and manufactured for the stores, a relevant LED light source should be used for visual colour matching between fabrics and products. Products can appear very different when viewed between different light sources and can show metamerism, which will not be picked up unless you assess samples using all the relevant light source options including LED lighting throughout the manufacturing stage and across the whole process.

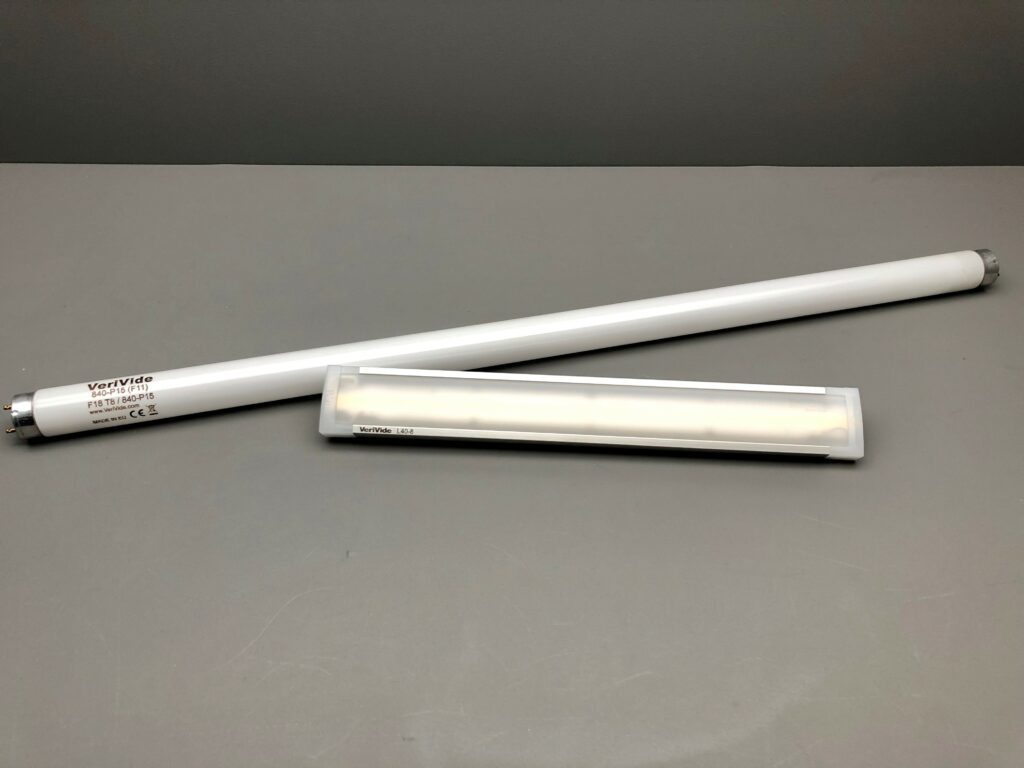

TL84 D65 L40-8 LED

VeriVide 840-P15 - 4000K, Fluorescent Point of Sale is to assess for metamerism and flare VeriVide CIE D65 Artificial Daylight - 6500K, will continue to be the primary light source VeriVide LED - 4000K, LED Point of Sale is now the secondary light source

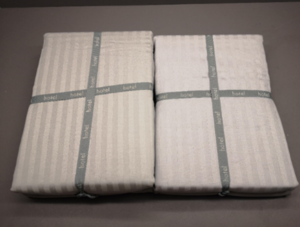

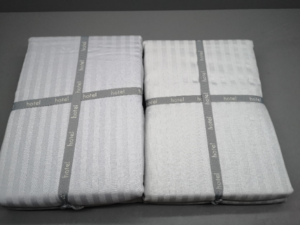

For example, look at these bed sheets. Are they cream, white, maybe grey? Under the LED light, the same product looks to have two different colours. Your product could look like this in store, which is ultimately going to affect sales, customer satisfaction and compromise your brands reputation. It is vital to incorporate LED lighting into your visual assessment!

‘Watt’ the Difference

You might think you can pop down to your local DIY store and pick up a few bulbs. Well, you can! But you will not get the results you need and want. The lighting industry tolerances for the output of LED bulbs is very wide and visually obvious. Sourcing LEDs locally will introduce inconsistency into the supply chain.

The L40-8 LED module is manufactured at the VeriVide HQ to very tight tolerances and specification, ensuring consistency across the process, from primary supplier to store. The following images show the difference in light emitted when our lighting cabinet is fitted with LED bulbs purchased locally in comparison to the VeriVide L40-8 LED bulb.

LED 4000K bulbs from local DIY Store VeriVide L40-8 LED 4000K bulb LED 4000k bulbs purchased online

In summary;

- If you are changing the light source in store, you must ensure your products are visually colour matched in that same lighting during every stage of manufacturing AND compared in all potential light sources the product could be marketed under or displayed

- Different versions of LEDs will produce different outcomes, ensure you buy industry standard tight tolerance LED bulbs to use in your lighting cabinet

Do not get caught LED-handed! Make sure you have consistency in your supply chain by not only using multiple light sources, including relevant point of sale lighting in your colour assessment cabinets, but ensuring that the correct LED light sources are being purchased too!

If you have any questions about LED lighting, our colour assessment cabinets or anything about VeriVide and our products, please contact us on enquiries@verivide.com or 0116 284 7790. And don’t forget to download and read our CAC & CAC LED Datasheets here!