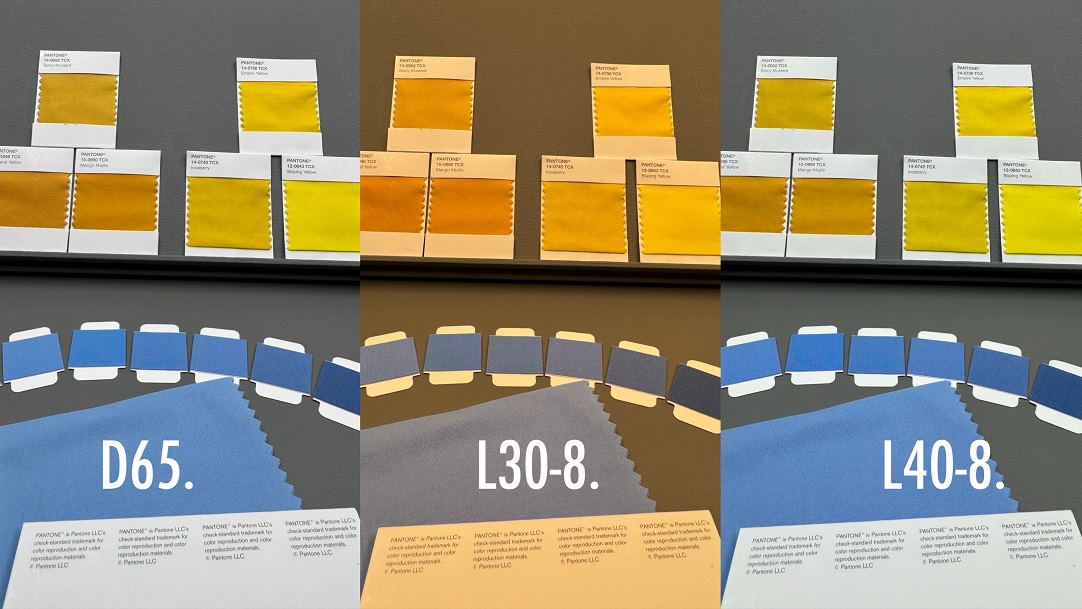

Standardised viewing conditions ensure your product represents the original concept or design in any environment. They refer to the specification for visual assessment which every brand and retailer should have and share with their supply chain. This document sets out the conditions for viewing the product including the angle of viewing, size of the sample, the type of colour standard and most importantly the light sources and viewing environment.

Using standardised viewing conditions, the same decision will be reached each time visual assessment occurs.

Textile Retailer

Standardised viewing conditions help you ensure that the garments you produce are as faithful a representation of the original design as possible. It is important to avoid metamerism and to be aware of how they will look under store lighting (POS).

Textile Manufacturer

Standardised viewing conditions, often specified by your manufacturer, ensure that you can accurately produce garments as intended. Removing costly re runs or corrections and even loss of business. They ensure that the fabric looks how it should under your client’s point of sale lighting and it does not suffer from metamerism.

Dyer

Standardised lighting conditions replicate the spectrophotometer conditions and ensure that the recipes you formulated from the spectral data match the intended colour. Your customers need the products to match the colour standard under multiple light sources avoiding metamerism. For many of your clients visual assessment is still key; spectral data alone does not give them peace of mind.

Flexographic Printer

Standardised lighting helps flexographic printers working with brand or spot colours ensure they meet the high standards expected. VeriVide’s specialist print and packaging range ensures that finished products are accurate representations of the original design.

Quality Assurance

For quality assurance specialists, visual assessment is a vital part of ensuring high-quality products. Assessing colour and also appearance, is a vital part of many companies quality assurance. VeriVide light booths are used by Food manufacturers to ensure consistency and quality of large volumes of products, sometimes comparing against standard images created in DigiEye. For those working with composites, visual assessment is used to check for flaws. In any industry, viewing a product can be the difference between product failure and the high-quality products their customers expect.

Technical Textiles

Technical Textiles manufacturers and end users use VeriVide light booths to highlight imperfections and colour issues. Visual assessment is a vital part of ensuring that standards are upheld and customers are happy. This is especially true in industries where perfection is expected by the end clients such as the luxury automotive industry.

Lithographic Printer

VeriVide CCC’s are used to ensure consistency of colour and quality of print runs against proofs. Use VeriVide CCC’s in showrooms to aid client presentations and demonstrate capability to build and retain business. In a highly competitive industry that is constantly in search of an advantage, standardised assessment conditions allow for consistent replication of colour and colour branding. Likewise, VeriVide products allow you to visually assess deviation of spot colours against colour standards as well as between proofs and samples from print runs.