Digital colour and appearance measurement at Techtextil

VeriVide’s DigiEye non-contact, digital colour measurement system is proven in use in many industry sectors including food and pharmaceuticals. Consequently it is specified by textile and associated manufacturers and retailers such as Adidas, Nike, Procter & Gamble, Unilever, Marks & Spencer, Heathcoat Fabrics and Ikea.

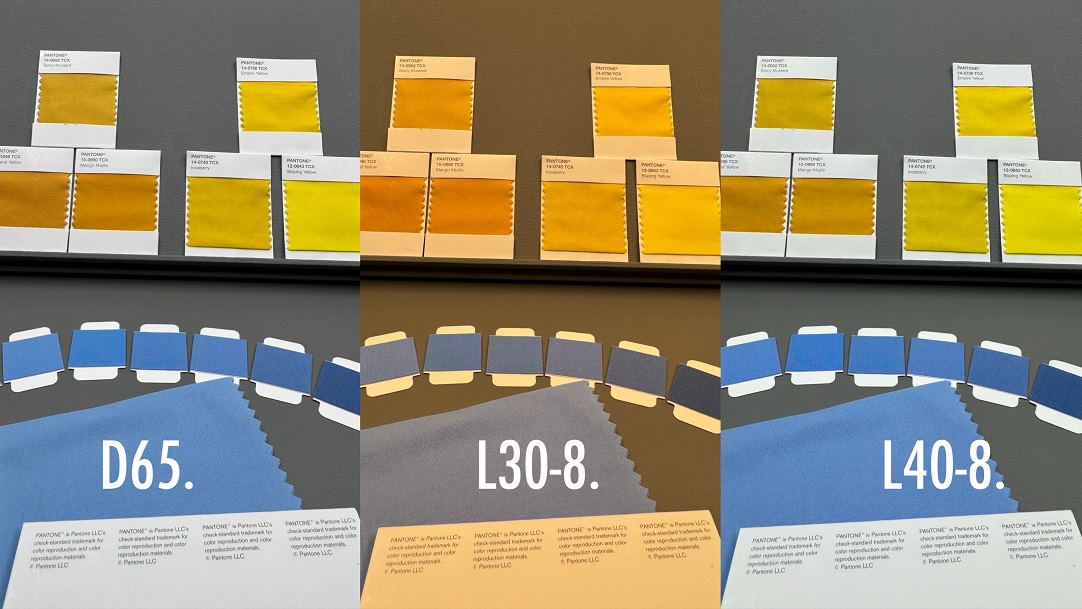

Its advanced yet easy-to-use technology can be an invaluable tool for designers, manufacturers and retailers in the technical textile and non woven sectors. DigiEye can assess the colour and appearance of ‘difficult’ surfaces and textures and as production technology advances will increasingly be the only effective means of doing so.

Discuss DigiEye with VeriVide at Techtextil in Hall 3.0 stand H43 on the BTMA Pavilion

To mention just a few examples, DigiEye can be easily configured to assess tapes, belts, ropes, nets, membranes, multi-layered composites, ‘smart’ textiles, recycled materials, coated textiles, technical safety fabrics including airbags, parachute and medical fabrics, and advanced packaging materials. The list could be much, much longer. The VeriVide team welcome the opportunity to discuss DigiEye with you at Techtextil.

VeriVide’s confidence in DigiEye’s super-power is summed up by VeriVide’s Paul Dakin: ‘Over the years we’ve developed DigiEye for a lot of industry sectors and have yet to meet a substance or material, solid or liquid, any size or shape, that DigiEye can’t assess. And it can provide better, quicker data than any other method.’ DigiEye can be particularly cost effective for innovative textile designers and technologists, and manufacturers wanting to push back technology barriers. Here, an advantage isn’t just the DigiEye system itself but the VeriVide expertise that created it.

‘The whole point about innovation is that it can take you into new areas where traditional methods of imaging, measurement and quality control may be too slow and inaccurate, if they work at all,’ adds Russell Thorpe. ‘The offer we make to anyone in technical textiles is simple: tell us what colour or appearance data you want, and we supply you with a customised DigiEye system that delivers it. We enjoy the challenge, and DigiEye is so versatile that we always come up with a winning solution.’

The main take-away for companies attending Techtextil 2015, is that DigiEye offers major benefits to any innovator, manufacturer or retailer in the technical textile sector.