Food color is an important factor influencing consumers; their verdict is universal: preferring colours to be consistent, accurate, and reliable. If your customers don’t like the color of your products, it is likely to be financially damaging your business.

Consequently, why gamble on color when instead you can choose the precise, consistent and repeatable approach of DigiEye?

DigiEye offers you results and data which are accurate, objective and quantifiable. This is supported with product imagery which can easy be communicated, throughout your global supply-chain.

Who are IFT?

IFT are the Institute of Food Technologists with a global mission to advance the science of food and its application. Based in Chicago they organise regular training courses, symposiums and expos.

VeriVide will be at IFT12 in Vegas on Booth 1369B from June 26th through to June 28th demonstrating DigiEye – the non-contact, non-destructive, digital colour measurement system.

DigiEye Applications

DigiEye has many proven applications for an exceptionally extensive range of foods and ingredients, these include:

- Quality Control

- Photographic Standards

- Tolerance Management

- Visual Inspection

- Product Research & Development

- Laboratory Analysis

- Instrumental Measurement

- Multi-Sample Evaluation

- Color Stability Analysis

- Post-Harvest Storage & Shelf Life Assessment Trials.

Mark Graham, our North American representative will be on our IFT Booth, together with Rowan Fisher and Russell Thorpe from our Sales and Application team in the UK.

So why not come along to Booth 1369B for a demonstration of the DigiEye System and talk to Mark, Rowan and Russell to hear how DigiEye is likely to have applications for your own food products and to hear how we can give your own business that all important competitive edge.

How Good is your Color Vision?

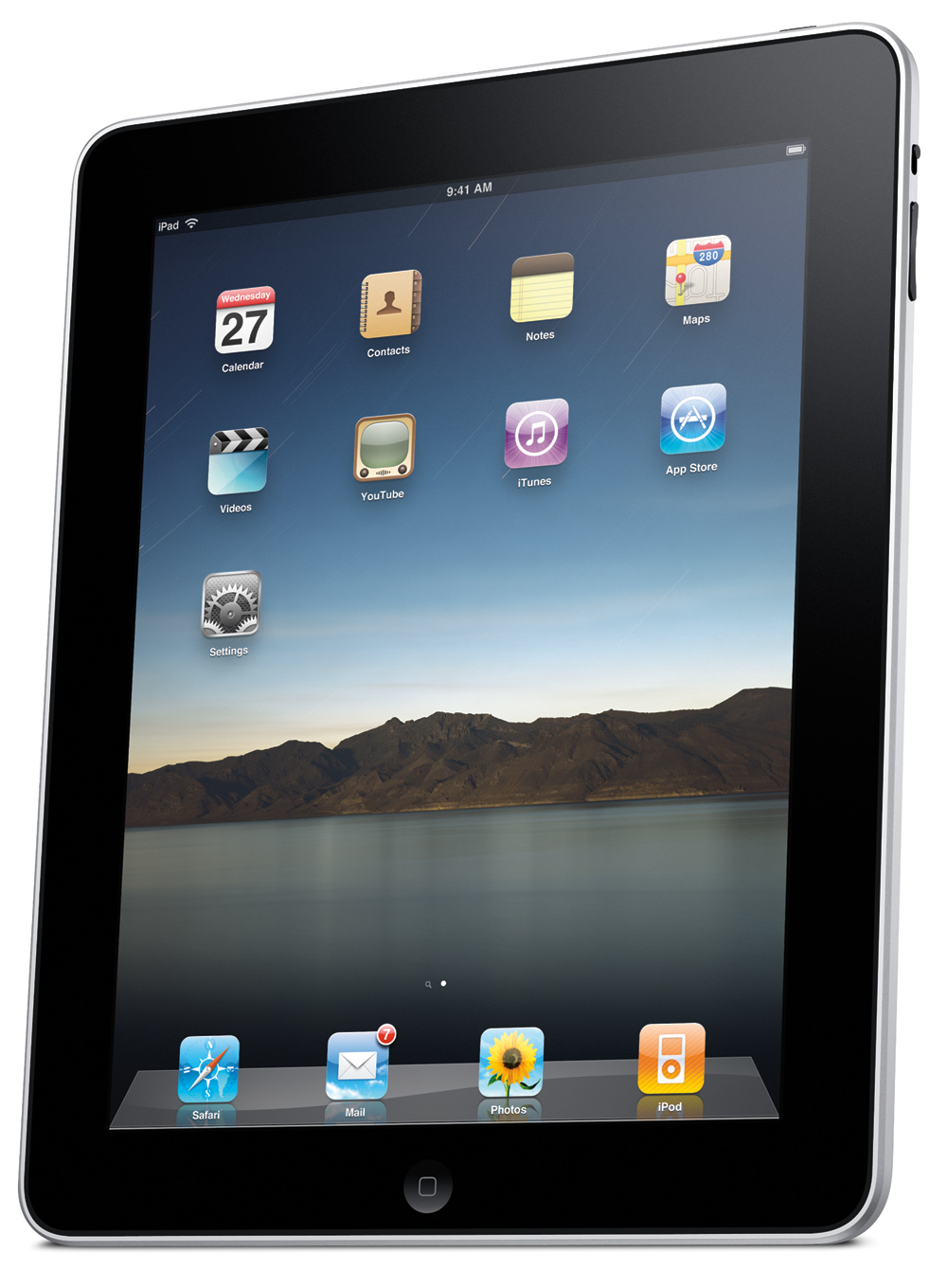

And if seeing a demonstration of the DigiEye System isn’t reason enough to come and see us … somebody visiting our booth at IFT12 will win a new iPad 3.

We have a competition to test your Color Vision – all using wonderfully diverse and colourfully vibrant food products.

- So if you think you can place seven Bananas in order of ripeness based on their color – you may win an iPad 3.

- If you are confident you can remember the color of a vibrant Red Pepper Purée – an iPad 3 could be yours.

- If you believe your color vision skills can enable you arrange bread with differing bake levels in the correct color order – you might be on your way to owning an iPad 3.

Feeling lucky?

What are the odds on your color assessment being spot on?

Come on and take a gamble, you are in Las Vegas! Try your luck and put your visual color assessment skills to the test with our fun competition.

DigiEye Food Applications

Used globally for diverse applications in a wide variety of Food Products, DigiEye has proven capability in the food industries below.

DigiEye is used by an independent food research institute for photographic references and research trials in locations in the UK and within Europe.

A US Cereal manufacturer uses DigiEye for the colour QC of cereals and snack foods. Also for the assessment of the percentage distribution of components on the visible surface of the products, such as fruit and enrobing.

A producer of fruit products and fruits juice, based in the United States, uses DigiEye for the assessment of dried fruit produce that are impossible to measure on a spectrophotometer due to their small, uneven nature.

Packaging & Stability

One of the world’s leading premium drinks businesses, based in the UK, uses the DigiEye System to assess the colour QC of packaging. This helps to protect the integrity of their brand.

A multi-national company, based in Europe, uses DigiEye to assess the colour stability of packaged and stored food in shelf-life research analysis.

The DigiEye System is used by one of the world’s leading supplier of flavours, fragrances and colourants, to assess liquid in bottles. Small confectionary items that are beyond the measurement capabilities of a spectrophotometer are also measured.

A long-establish global food producer, based in the States uses the DigiEye System for the assessment of tinned products. They analyse the effects of varying process treatments upon the colour of their products – beans, soups and spaghetti.

A global food producer uses DigiEye in their R&D departments in different European countries, to assess produce that cannot be measured on a spectrophotometer. Furthermore, it is also used for major, and successful, research projects. One of which is the colour of products such as soup with vegetable and fruit inclusions.

DigiEye is used by a UK multi-site bakery to ensure product consistency though colour accurate photographic imaging of their bakery products. Subsequently, they produce photographic reference standards for Quality Control.

A multi-site bakery & confectionary manufacturer supplying the Nordic regions and Russia, use DigiEye for Quality Assurance. This is primarily through the use of photographic reference standards.

Largest food producer in the UK have multiple DigiEye systems which are used for photographic references and for Quality Control of product colour. Used particularly for Baked Beans and Jars of Cooking Sauce.

German based producer of natural colourants uses the DigiEye System used for assessing the colour of difficult substrates. These include small sweets and confectionary items that cannot be measured using a spectrophotometer.

Meat, Fish and raw ingredients

A producer of cooked and processed meat, based in Colombia, uses DigiEye for Color Quality Control and Color Measurement.

A Swedish food research institute uses DigiEye for analysis of the colour of textured, non-solid color and liquidised samples.

A Seafood processing research institute, based in Scandinavia uses DigiEye for research into the influences of the colour of fish flesh. Additionally, for shelf life studies of various products stored in variable conditions.

A company in North America, with global sites, use DigiEye, for the color assessment of raw, frozen and cooked vegetables.

The UK’s largest family owned bakery uses the DigiEye Systems for photographic reference standards. This is to control production from the ovens using a ‘traffic light’ system – ‘pass’, ‘attention needed’ or ‘fail’.

Scientific Research of foods

DigiEye is used by a technological research council in Turkey for scientific research projects of food products.

A large beverage company in Colombia, uses DigiEye for the Color Quality Control of their soft drinks.

.

Download the DigiEye for Foods datasheet today! Or contact Russell Thorpe on enquiries@verivide.com to find out how DigiEye can analyse your food product.